Products

Quartz Crucible manufacturing method

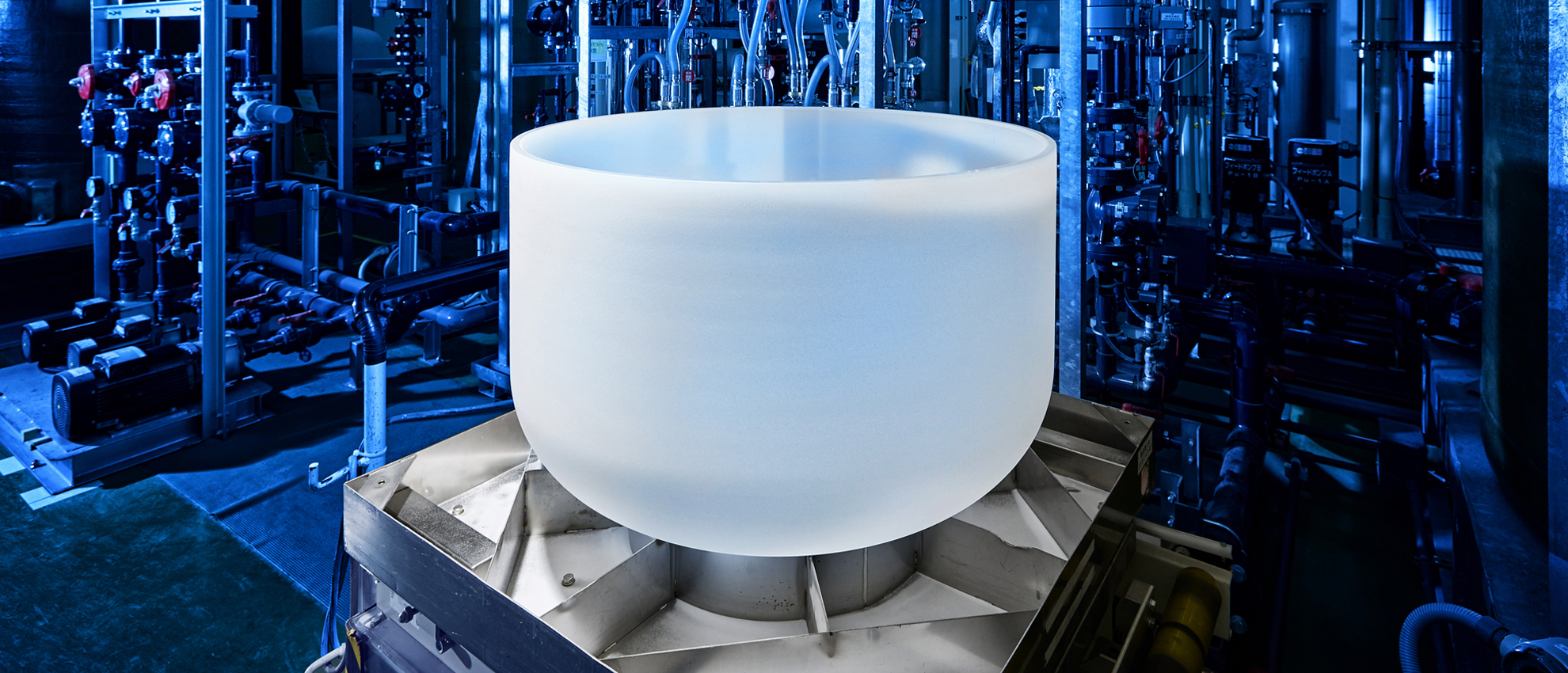

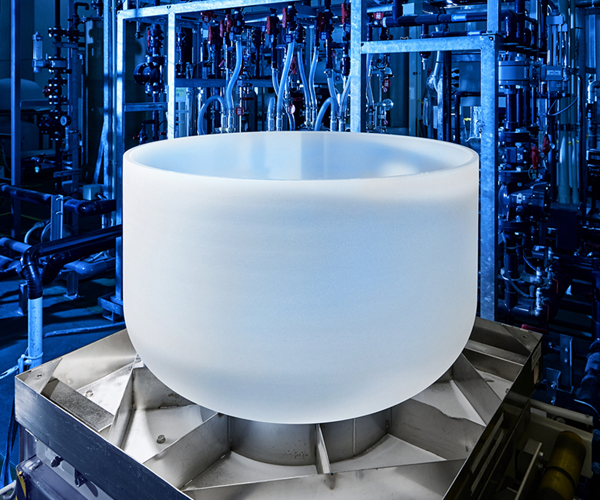

What is Quartz Crucible?

Semiconductors make many things in our daily lives possible. They’re used in the electrical products and household appliances all around us, in automobiles, and in the handling of huge volumes of PC data. They’re also used for the vivid images displayed on LCD TV screens, and for the many functions incorporated in smartphones.

Semiconductor devices are made by forming minute electrical circuits on a foundation called silicon wafers, which are made by thin slicing single crystal silicon.

It can be said that these single crystal silicon are important materials that are the starting points for semiconductors.

Single crystal silicon are grown by filling Quartz Crucible with high-purity polycrystalline silicon, and heating and melting it with temperatures of around 1500℃ in a pulling device.

Quartz Crucible are quartz glass containers used when manufacturing single crystal silicon wafer. They are essential for semiconductor manufacturing.

Major features of JSQ crucibles

The purity and bubble level of the transparent layer can be controlled

depending on the intended use.

Our company suggests crucibles that meet your needs and intended usage. These suggestions come from a wide range of quality Quartz Crucibles, which include types of raw material powders, various melting conditions, and combinations of various finishing methods.

In addition, while working together closely with our customers, we analyze the relationship between single crystal silicon yield and quality, and crucible quality. We further use these results as feedback for product quality, and always develop and provide products that suit your needs.

We ship our products not only within Japan, but also to various overseas locations including the United States, Europe, and Asia. We have high evaluations and trust from our customers all over the world.